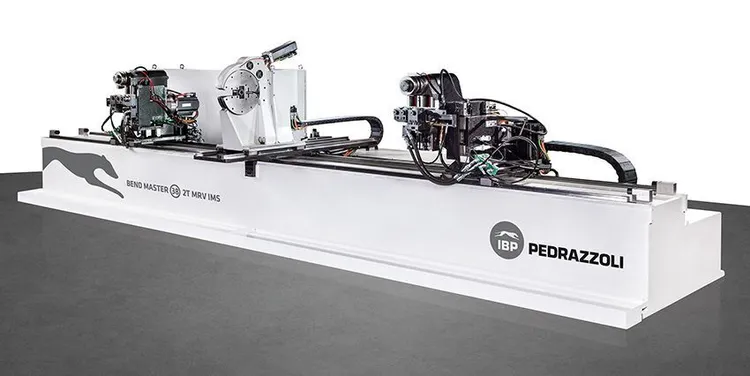

Introducing the Pedrazzoli Bend Master 38, featuring advanced electric axis control enabling simultaneous clockwise and counter-clockwise bending in a single cycle. Its ingenious multi-stack tooling design excels in creating both fixed and variable radius bends. Crafted from top-tier steel, the machine’s framework guarantees durability.

Every element of the Bend Master 38 is meticulously machined to precise standards, with dimensions verified by cutting-edge measuring systems. The linear guide movements showcase re-circulating ball spheres, brushless motors, and a robust mechanical composition. For better precision, a tool post strengthening tie rod is included.

● Clockwise and counter-clock wise bending

● Variable and multi-radius bending in the same cycle

● Compact bending head design accommodates most applications

● Intuitive IMS touchscreen control

● Electric axis for greater precision

● FANUC drive controllers for improved reliability

● Innovative tube stop allows positioning from rear of carriage (optional)

● Automatic adjustment of tools

● Boost for tight radius bending with synchronized control of axis

● Torque controlled positioning of carriage on incline tooth precision gear rack

● Controlled torque of clamp die and pressure die

● Automatic lubrication work piece

● Rapid coupling system for quick mandrel rod installation

● Safety light barriers with programmable work zone

● Central lubrication of guides and ball screws

Capacity: 1.5″ x .095

CW and CCW Bending: Right Left Independent

Maximum CLR CW: 6″

Maximum CLR CW-CCW: NA

Minimum Inside Radius with Standard Spindle: 1.2″

Variable Radius Bending: Yes

Maximum Bend Angle: 180°

Min. Distance Between Bends: 0.5 x Diameter

Max. Distance Between Bends: 204″

Max. Stroke Clamp Die: 3.15″

Max. Stroke Mandrel: Machine without Mandrel

Section Modulus cm³: 2.33

Horizontal Head Travel: 19.6″

Vertical Head Travel: NA”

Number of Bend Heads: 2

Punching: Available

Electrically Controlled Axes: 8

Drive Controllers: FANUC

Precision of Electric Axis: + or – .1 mm

Carriage Speed: 32.8″ / sec

Bend Arm Speed: 160° / sec

Tube Rotation Speed: NA

Central Clamp Rotation: 250° / sec

Maximum Tool Stacks: 2-3

Software: IMS

Webcam: Yes

Max. Tube Length on Front Stop: 204″

Max. Tube Length on Rear Stop: NA

Machine Dimensions: 257″ x 78″ x 57″

Height of Work Plane: 47″

Weight: 8,400 lbs

Power: 480V 53kw

Hydraulic Reservoir: 39 gallons

We use cookies to improve your experience. Privacy Policy.